WHAT CAN HUDDINGE STEEL DO?

HEA-beams are flexible in terms of design and configuration.

At Huddinge Steel we offer quality assignments in cutting, welding, and painting of HEA-beams.

The HEA-beam is cut using band saws and circular saws. We have optically controlled cutting machines that enable finely cut details. We deliver forged blanks in different shapes and qualities.

We cut and clip to the measurements and angles you need. We also offer welding of HEA-beams according to your wishes.

At Huddinge Steel we have access to IWS competence for welding supervision for EXC2 in accordance with SS EN 1090-2. We also perform painting of structures with a length of up to 22 meters and a width of up to 4 meters. The painting is done in Huddinge and we do both priming and painting, class 1 to 5.

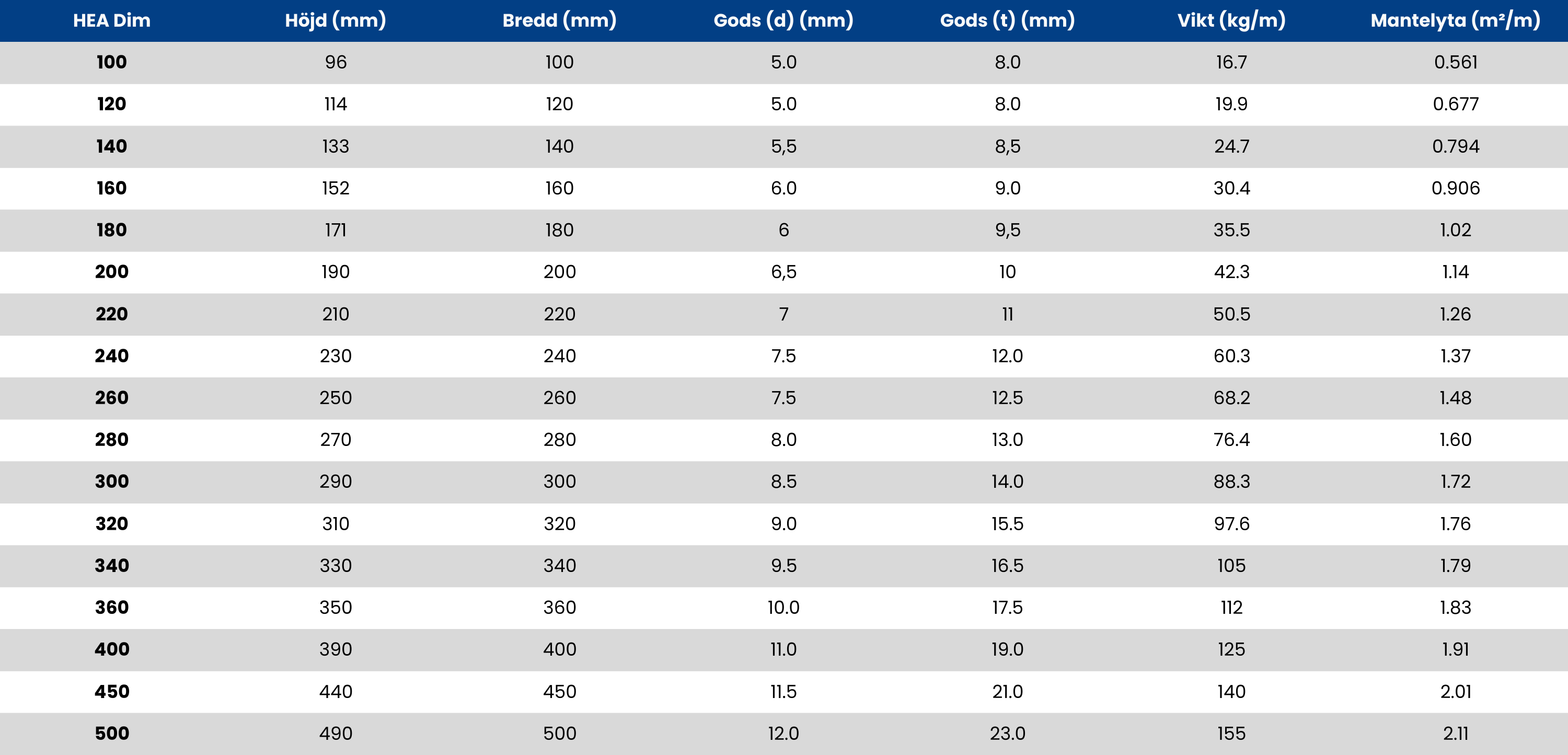

OUR MOST COMMON HEA-BEAMS

HEA-BEAM 140

Width: 140mm Height: 133mm Weight: 24.7 kg/m

HEA-BEAM 160

Width: 160mm Height: 152mm Weight: 30.4 kg/m

HEA-BEAM 180

Width: 180mm Height: 171mm Weight: 35.5 kg/m

HEA-BEAM 200

Width: 200mm Height: 190mm Weight: 42.3 kg/m

HEA-BEAM 220

Width: 220mm Height: 210mm Weight: 50.5 kg/m

HEA-BEAM 240

Width: 240mm Height: 230mm Weight: 60.3 kg/m

HEA-BEAM 300

Width: 300mm Height: 290mm Weight: 88.3 kg/m

FAQ

DIFFERENCE HEA, HEB, AND HEM BEAMS

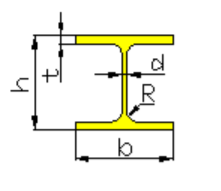

The difference between HEA, HEB, and HEM beams lies in the thickness of the material and the weight. HEB beams have thicker material thicknesses and higher weight than HEA beams. HEM beams are the thickest variant and have the thickest material thickness and the highest weight.

HEA, HEB, and HEM beams have the same areas of use but the thicker variants are used when higher loads require a thicker dimensioning.

HOW MUCH CAN A HEA-BEAM BE LOADED?

The load-bearing capacity of a HEA-beam is directly related to its dimensions. Generally speaking, the larger the dimensions a HEA-beam has, the greater load it can carry. This is because the increase in the beam's height and width provides a larger cross-sectional area, which in turn leads to increased strength and load-bearing capacity.

HEA-beams are specified in different sizes (120, 140, 160…) which refers to the beam's height. Other dimensions such as the width and thickness of the flanges vary in relation to the height.

It's important to note that the load-bearing capacity also depends on other factors, such as the quality of the material, the nature, and direction of the load, and how the beam is supported.

WHAT DIFFERENT TYPES OF BEAMS ARE THERE?

In addition to H-beams, we stock UPE, IPE, and UNP beams with the possibility to bring in others on request.